Thermography & Specialised scanning

Thermography & Specialised scanning

Thermoscan is a key partner to Risk Mitigaters and our approach to risk mitigation.

With many fires the result of defective plant, wiring or switchboards, many insurers insist on annual certification and repair to defects.

In fact, failure to take reasonable measures to ensure this risk is eliminated may result in an insurance claim being denied.

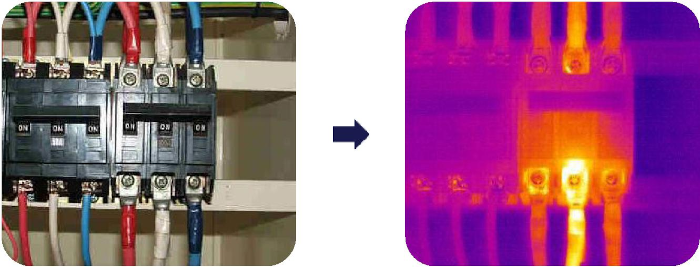

Electrical thermography can play a critical role in ensuring consistent, safe and long-lasting operation of mechanical and electrical equipment by proactively identifying any potential defects. All looks well, but something in using the infrared camera, this picture below is about to fail the defect is revealed.

Thermoscan

Provide services to over 6,000 clients nationally and over 9,000 Thermoscan® inspections each & every year.

- 90% of reports are delivered within 24 hours.

- Areas serviced are throughout Australia, New Zealand and the Pacific Islands.

Independence, Equipment and Reporting

All our cameras are high performance FLIR thermal imaging cameras, all with temperature capabilities to 1200°C; 1500°C or 2000°C. We focus on our widely acclaimed Thermoscan® inspection and reporting process. Our business is to inspect; detect and help you protect your infrastructure. Our impartiality is assured as we are solely focused on this area. We are not promoting our ability to perform remedial works or seeking "do & charge" work. Thus, you get the absolute expert in the trade. We advise and report with clarity and precision leaving you with the full information to make your decisions. Our reports are high quality and are delivered via e-mail.

Certification — Quality, Safety and Environmental

- AS/NZS ISO 9001:2015, AS/NZS 45001:2018 and AS/NZS 14001:2015 Certified

- AS/ NZS ISO 9001:2015, ISO 45001:2018

- Environmental Certification ISO 14001:2015.

"Best Ultimate Value"

Thermoscan® Inspection Services is uniquely placed to perform this scope of work. Our resources and knowledge coupled with our proven implementation methodology enables us to offer high quality service at economical rates.

Why Thermal Scanning?

Thermal imaging as part of a regular maintenance protocol ensures increased productivity as a result of reduced equipment failure and improves safety by avoiding dangerous breakdowns and accidents.

BE BENEFITS OF THERMAL IMAGING AS PART OF A REGULAR MAINTENANCE PROTOCOL

- Reducing unplanned downtime due to asset failure and allowing planned downtime.

- Reduce potential customer or revenue loss through service failure

- Increased Longevity & useful life of assets

- Reducing repairs and frequency of overhaul requirements for assets.

- Improving productivity rates and system availability.

- Improving safety for staff and avoiding catastrophic failures and damage to property. (eg. industrial fires)

- Proactively identifying building water leaks and heat loss.

- Increase compliance with insurance requirements.

- Reduce the likelihood of insurance claims not being paid.

- Maximize return on net assets

Find out more - speak to Risk Mitigaters today

Login

Login